Product portfolio

Online consultation

Sale 1

![]() 0888 703 166

0888 703 166

Sale 2

![]() 0888 508 366

0888 508 366

Hotline

![]() (028) 3620 9501

(028) 3620 9501

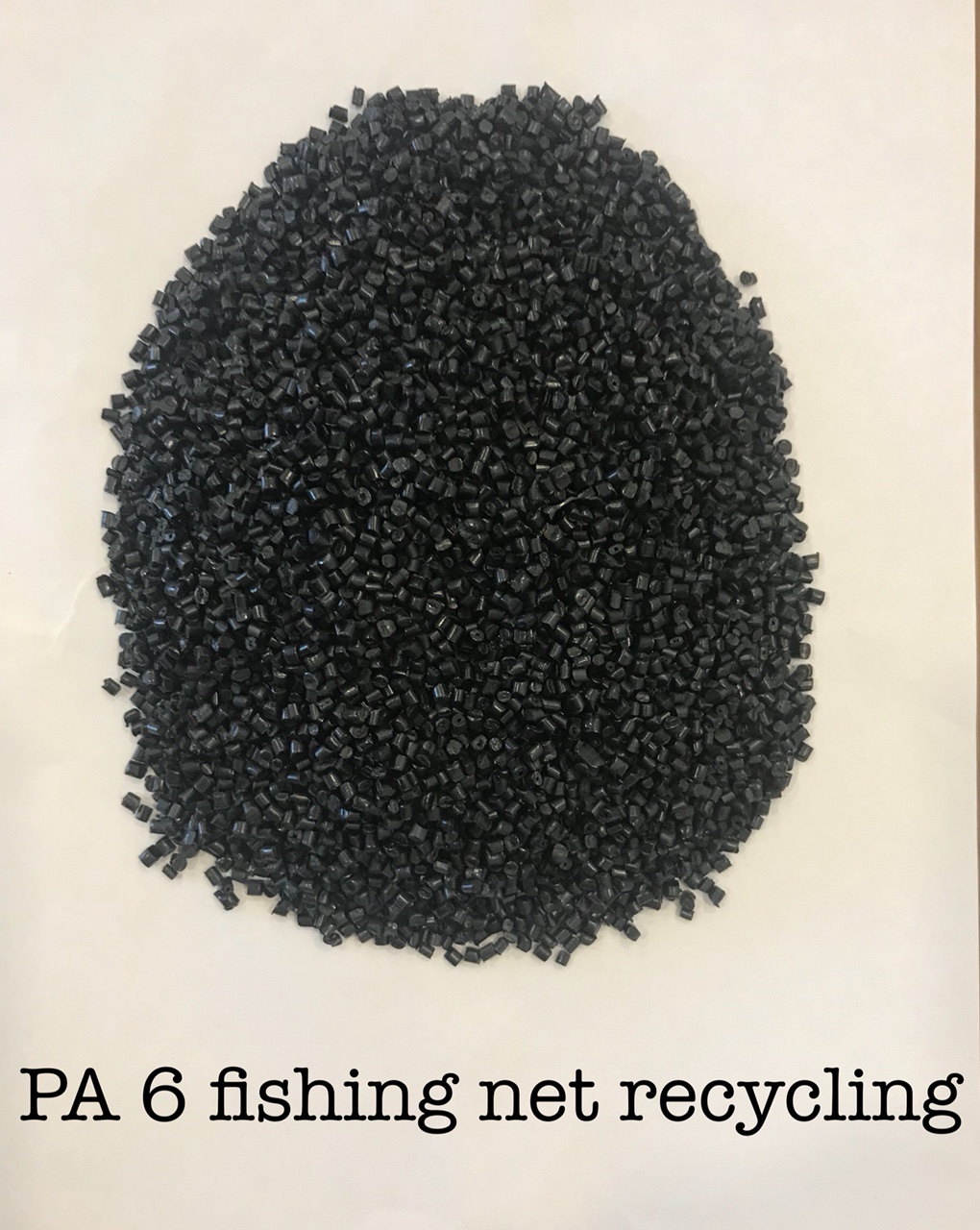

PA6 PLASTIC RESIN

Nylon 6 or polycaprolactam is a polymer developed by Paul Schlack at IG Farben to reproduce the properties of nylon 6,6 without violating the patent on its production. (Around the same time, Kohei Hoshino at Toray also succeeded in synthesizing nylon 6.) It is a semicrystallinepolyamide. Unlike most other nylons, nylon 6 is not a condensation polymer, but instead is formed by ring-opening polymerization; this makes it a special case in the comparison between condensation and addition polymers. Its competition with nylon 6,6 and the example it set have also shaped the economics of the synthetic fiber industry.

Properties

Nylon 6 fibres are tough, possessing high tensile strength, as well as elasticity and lustre. They are wrinkleproof and highly resistant to abrasion and chemicals such as acids and alkalis. The fibres can absorb up to 2.4% of water, although this lowers tensile strength. The glass transition temperature of Nylon 6 is 47 °C.

As a synthetic fiber, Nylon 6 is generally white but can be dyed to in a solution bath prior to production for different color results. Its tenacity is between 6 and 8.5 gm/den with a density of 1.14 gm/cc. Its melting point is at 215 °C and can protect heat up to 150 °C on average.

Applications

Plastic parts are made with these polyamides are used in various industries like:

· Transportation

· Electronics & Electrical

· Consumer goods

· Building & Construction

· Packaging